PRODUCTS |

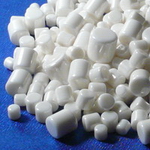

YSZ Media

Yttria Stabilized Zirconia

Typical Properties of YSZ Grinding Media

Tetragonal zirconia polycrystal (TZP) – outstanding mechanical properties

Pure zirconium dioxide exists in three crystal phases at different temperatures. At high temperatures (from 2370°C to its melting point at 2680°C) the material has a cubic structure (c-ZrO2), at intermediate temperatures (from 1170 to 2370°C) it has a tetragonal structure (t-ZrO2), while at low temperatures (below 1170°C) the material transforms to the monoclinic structure (m-ZrO2). The volu

me expansion caused by the cubic to tetragonal to monoclinic transformation induces large stresses, and causes pure zirconia to crack upon cooling from high temperatures. This destroys the mechanical properties of fabricated components and makes pure zirconia useless for any structural or mechanical application. Several oxides are added to zirconia to stabilize the tetragonal and/or cubic phases at room temperature: yttrium oxide (Y2O3), cerium oxide (Ce2O3), magnesium oxide (MgO), and calcium oxide (CaO), amongst others. me expansion caused by the cubic to tetragonal to monoclinic transformation induces large stresses, and causes pure zirconia to crack upon cooling from high temperatures. This destroys the mechanical properties of fabricated components and makes pure zirconia useless for any structural or mechanical application. Several oxides are added to zirconia to stabilize the tetragonal and/or cubic phases at room temperature: yttrium oxide (Y2O3), cerium oxide (Ce2O3), magnesium oxide (MgO), and calcium oxide (CaO), amongst others.The material of YSZ grinding media are tetragonal zirconia polycrystal (TZP) made from zirconium dioxide (ZrO2) to which yttrium oxide (Y2O3) is added as stabilizing agent, achieving outstanding strength and fracture toughness among ceramic materials. Besides these, yttria stabilized tetragonal zirconia polycrystal (Y-TZP) offers the traditional ceramic benefits of high hardness, excellent chemical and wear resistance, and good frictional behaviour.

The high fracture toughness of Y-TZP ceramics is attributed to stress induced transformation of the tetr

agonal (t-ZrO2) phase to the monoclinic (m-ZrO2) phase in the stress field of propagating cracks. The m-ZrO2 phase has a larger volume than the t-ZrO2, so it compresses the crack and drasticallly impedes the crack growth, because the energy necessary for further crack growth drastically increases. This phenomenon popularly known as "transformation-toughening". agonal (t-ZrO2) phase to the monoclinic (m-ZrO2) phase in the stress field of propagating cracks. The m-ZrO2 phase has a larger volume than the t-ZrO2, so it compresses the crack and drasticallly impedes the crack growth, because the energy necessary for further crack growth drastically increases. This phenomenon popularly known as "transformation-toughening". The only disadvantages of this material are its fast degradation in moist environments at ~ 200–300 °C (so-called hydrothermal degradation or ageing), and its relatively high cost due to its manufacturing process.

Hydrothermal degradation is the autocatalytic transformation of the metastabl

e t-ZrO2 to the equilibrium m-ZrO2 phase at a free surface held in a moist atmosphere at elevated temperature. e t-ZrO2 to the equilibrium m-ZrO2 phase at a free surface held in a moist atmosphere at elevated temperature. Higher quality grinding media do cost more, but they provide great long-term benefits that easily justify their higher initial cost. A lower cost per kilogram of beads can result in a significantly higher cost per kilogram of finished products produced in the long run. Using an inferior grade of grinding media can result in poor grinding, low quality mill output, reduced productivity, damaged agitation bodies, excessive mill wear, clogged screens, etc.

As with all other advanced ceramics, the attainment of the desired properties is strongly dependent on both the raw materials and the fabrication techniques.

First quality raw material – first quality grinding media

Our yttria stabilized zirconia milling media are produced by using a proprietary manufacturing process from the highest purity and super-fine raw materials. Hence, on the one hand, it is almost free from contamination of impurities such as Fe2O3, SiO2, Na2O, MgO, and any kind of heavy metals, on the other hand, the fine grain size allows for extremely smooth surfaces.

Figures are reference values. Property values vary somewhat

with method of manufacture, size, and shape of grinding body

We would like to emphasize that our materials are very high density zirconium oxide media, which are different from the alternative products of similar composition but lower physical properties.

Alternative products – lower density yttria stabilized zirconia

Lower quality yttria stabilized zirconia grinding media are characterized by a density of 5.7-5.8 g/cm3, 950-1150 Vickers hardness, 800-1000 MPa flexure strength, and a fracture toughness of 3-6 MPa√m. Of course, these alternatives are also available with us.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOBORAN LTD Miskolc, Hungary info@noboran.com |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||